This topic is purely about the different forms of

pontil, the tool used to hold the glass for finishing work after removal from the

blowing iron.

Collectors refer frequently to the lump of glass or snapping scar as the pontil but that is inaccurate, Hodkin & Cousen (will be my primary source in this post) name the lump of glass,

parison, used to connect the pontil to the blown globe as "

Bull's Eye", a better name and

presumably derived from the result on blown window glass.

For bottles the pontil consists of a split iron cylinder attached to the end of an iron rod. The fixed diameter being set to the size of the bottle to be finished. Leaving no Bulls Eye. Prior to full automation the Punty Feeder was a machine that made the gather on a pontil rod and fed this gather into a blowing machine.

Fixed sized gripping pontils are fine for standard size production. For more flexibility a sprung arrangement would be used and some would have prongs rather than a split cylinder, some gripped the outer edge of the base but others were smaller and typically left a mark of 3, 4 or more indentations.

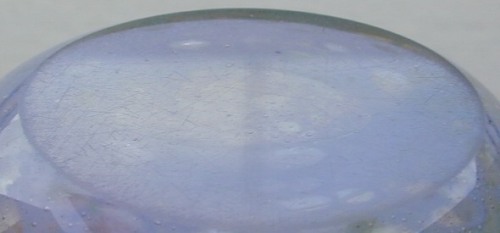

The pontil rod that leaves the snap-off scar or a raised bull's eye

use a small piece of glass gathered to the end of the pontil to create the join to the parison while it is still on the blowing pipe. After finished the object is snapped off and the remaining bull's eye has to be finished of by grinding.

n.b. the pit in this example was caused by the break off.

And maybe polishing of completely removing any trace

Terminology varies from country to country and glassworks to glassworks and hopefully other will add (or correct any errors above) more information.